How does High pressure suspension mill work?

Source:http://www.chinaraymondmill.co Author:GreatWall Posted:2015-05-26 Views:

Structure

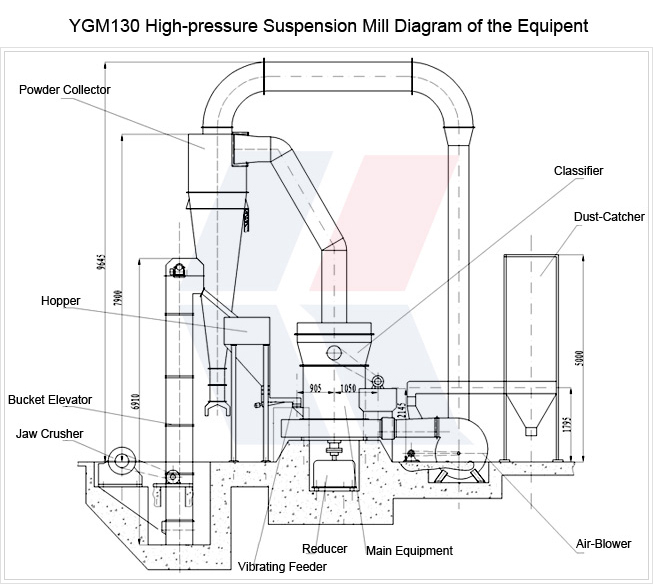

A set of YGM High-Pressure Suspension Mill consist of main frame, decelerator, powder separator, air blower, jaw crusher, bucket-elevator, vibrating feeder, hopper, bag filter, pipe-devices, motor and electric control panel, etc.

Operation Principle

Firstly, raw material should be crushed by the jaw crusher to the size specified, then the crushed stuff is elevated into the hopper by the bucket-elevator, through vibrating feeder, evenly and continuously into the grinding chamber for powder-processing. After this, the ground stuff is carried by the air flow from the blower into the separator for screening. The fine powder is blown into the cyclone collector and is poured out through the output-powder valves as the final product and the rough stuff after the screening will be recycled back into the grinding chamber for regrinding. The airflow system is closely sealed up and circulated under condition of negative and positive pressure.

Because the stuff contain some moisture, and the heat generated during the grinding process makes the moisture evaporated, what’s more, the pipeline joints are not airtight and therefore the external air is sucked in, all these will increase air-current in circulation and disturb the circulation balance, the balance of the air current in circulation can be realized by adjusting the pipeline of the extra air current between the blower and the grinder mainframe. After that, the powder carried by the extra air current will be collected by the dust filter. At the same time, the air current will be charged into atmosphere after purification.

The working picture as follow:

More information or questions, CONTRACT US.

Other relevant words: jaw crusher, cone crusher, Diesel engine crusher, Roll crusher